We only have one planet, and we’re doing what we can to respect it. At Radley, creating beautiful, long-lasting bags comes with responsibility. Guided by our Environmental, Social and Governance (ESG) strategy, we’re working to reduce our impact at every stage of our process, from design to delivery.

Materials That Matter

We choose materials for their quality and lower environmental impact.

- All the leather we use is a by-product of the food industry and certified by the Leather Working Group – the world’s leading environmental certification for the leather manufacturing industry.

- We source from tanneries that meet strict production standards set by the Leather Working Group.

- We never use exotic or endangered skins. Any embossed textures you see, such as mock-croc, are created from bovine hides.

- Our Radley Responsible collection continues to grow each season, with non-leather styles crafted from recycled polyester and lower-impact materials like water-based PU.

Smarter Production

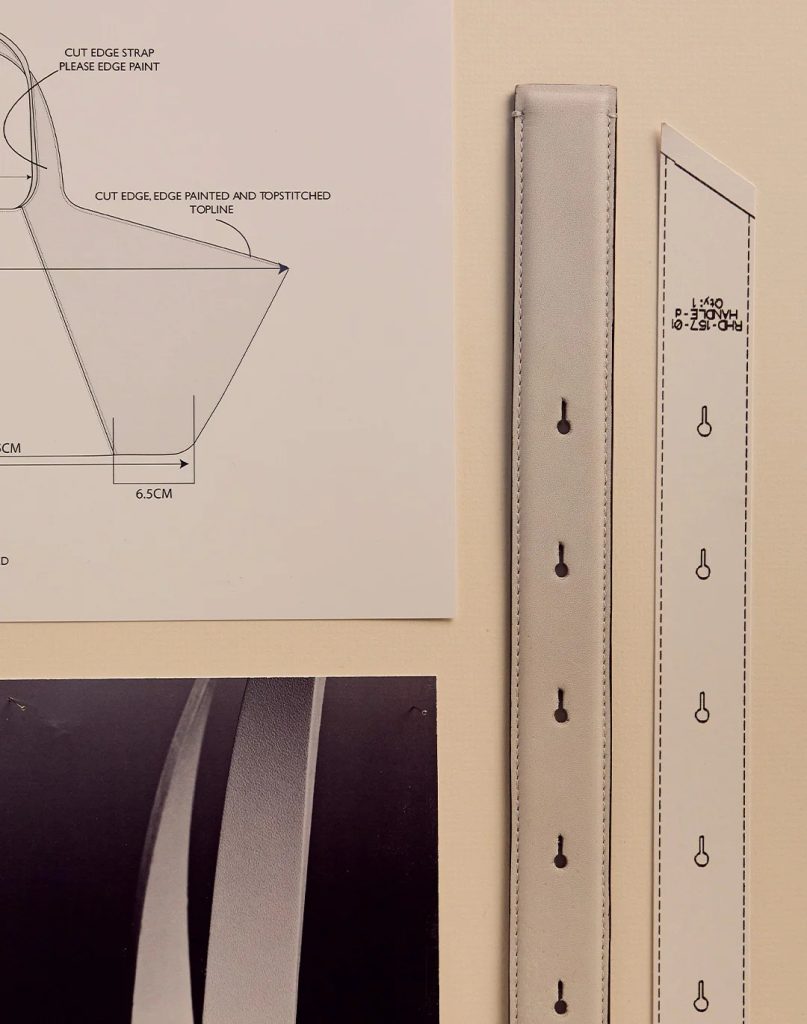

We design with intention and efficiency.

- Our London Design Studio uses surplus and leftover materials wherever possible. For example, The Chancery bag in Dark Oak from our Autumn-Winter 2025 collection is handcrafted from excess leather from previous production runs. Our Patchwork styles – Liverpool Street, Beaton Close, and Westwell Lane – are also thoughtfully crafted using leather offcuts.

- Our production planning helps minimise waste, from the way we cut leather to how we use one piece across multiple designs.

- By planning ahead, we can choose slower and less carbon-heavy transport options. Sea freight is prioritised over air whenever we can.

A Carbon-Conscious Future

We’re growing, but we’re working to reduce our carbon footprint at the same time.

- We move most of our finished goods by sea rather than by air. 84% of our goods from May 2024 – May 2025 were shipped by sea.

- We plan shipments to fill containers as efficiently as possible and reduce the number of journeys